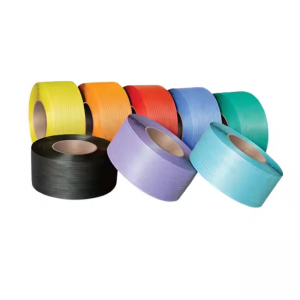

Product profile

The PP strap band (Polypropylene strap band) is a type of plastic strapping commonly used for bundling, securing, and packaging goods. It is made from polypropylene, a durable and flexible thermoplastic polymer.

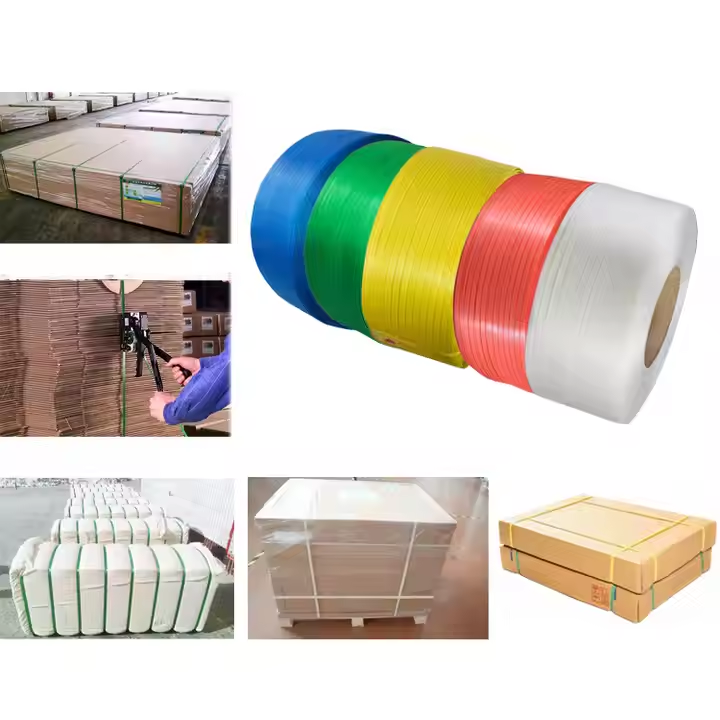

Product application

- Choose the right width & thickness – Depending on the load weight and application.

- Wrap around the items – Secure the strap around the package or pallet.

- Tensioning – Use a manual tensioning tool or machine to tighten the strap.

- Sealing – Secure the ends using a sealer (heat sealing or friction welding for a strong bond)

Why need use the pp strap band

- Cost-effective – Cheaper than steel or polyester strapping.

- Lightweight – Easy to handle and transport.

- Moisture & chemical resistant – Suitable for humid or corrosive environments.

- Good elongation – Absorbs shocks during transit.

- Recyclable – Environmentally friendly compared to metal straps.

The advantage of pp strap band

Company profile