Paper dunnage bags are made out of two components, an inner component that consists of a polyethylene inner bag, the outer component is a paper bag. The outer bag is made of the highest quality, light weight kraft paper of high tensile strength. The bags come in different strengths and varieties and can be made in any special size. The inner component provides optimum pressure, and the outer component provides optimum strength. For use in the chemical industry, paper bags can be polycoated. A polycoat will make the bag resistant to specific chemicals.

| )Brand | JahooPak |

| 2)Outside Materials | 75g Kraft Paper Laminated 75g PP Woven Fabric |

| 3)Inner Materials | 70um PA Film |

| 4)Body Color | Nature Brown Color |

| 5)Valve | Traditional Standard Valve or New Inflate Valve |

| 6)Work Pressure | 3 PSI |

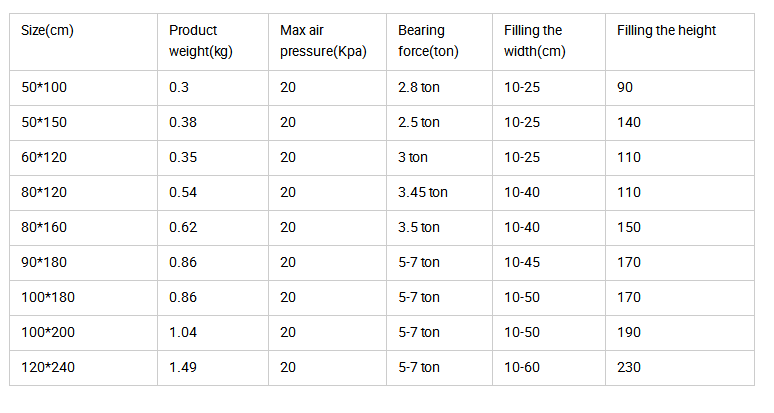

| 7)Size | 80*120cm or customized acceptable. |

| 8)Shipping Way | By sea/By air for mass production |

| DHL/Fedex/TNT/UPS/EMS for samples | |

| 9)Delivery Time | About 7-10 days for first 1*20GP shipment. |

| 10)Payment | T/T,L/C, Paypal/ Western Union and Etc. |

| JahooPak Advantage | 1.98% customers’ satisfaction. |

| 2.Good quality meet with Europe, America, Mid East, Asia Market Standards and Demands. | |

| 3.Wonderful 14 years market experience help you easy to start business. | |

| 4. Flexible size with your Logo Printing on. Easy to make your own brand |

Product Details

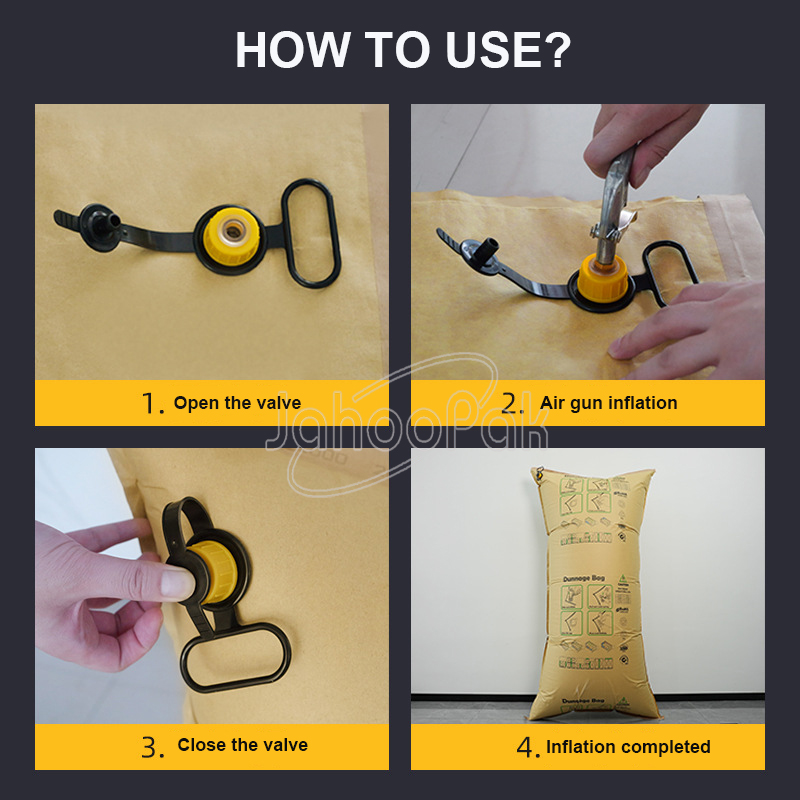

How To Use?

Quality Control

Production Line

Application

Packing