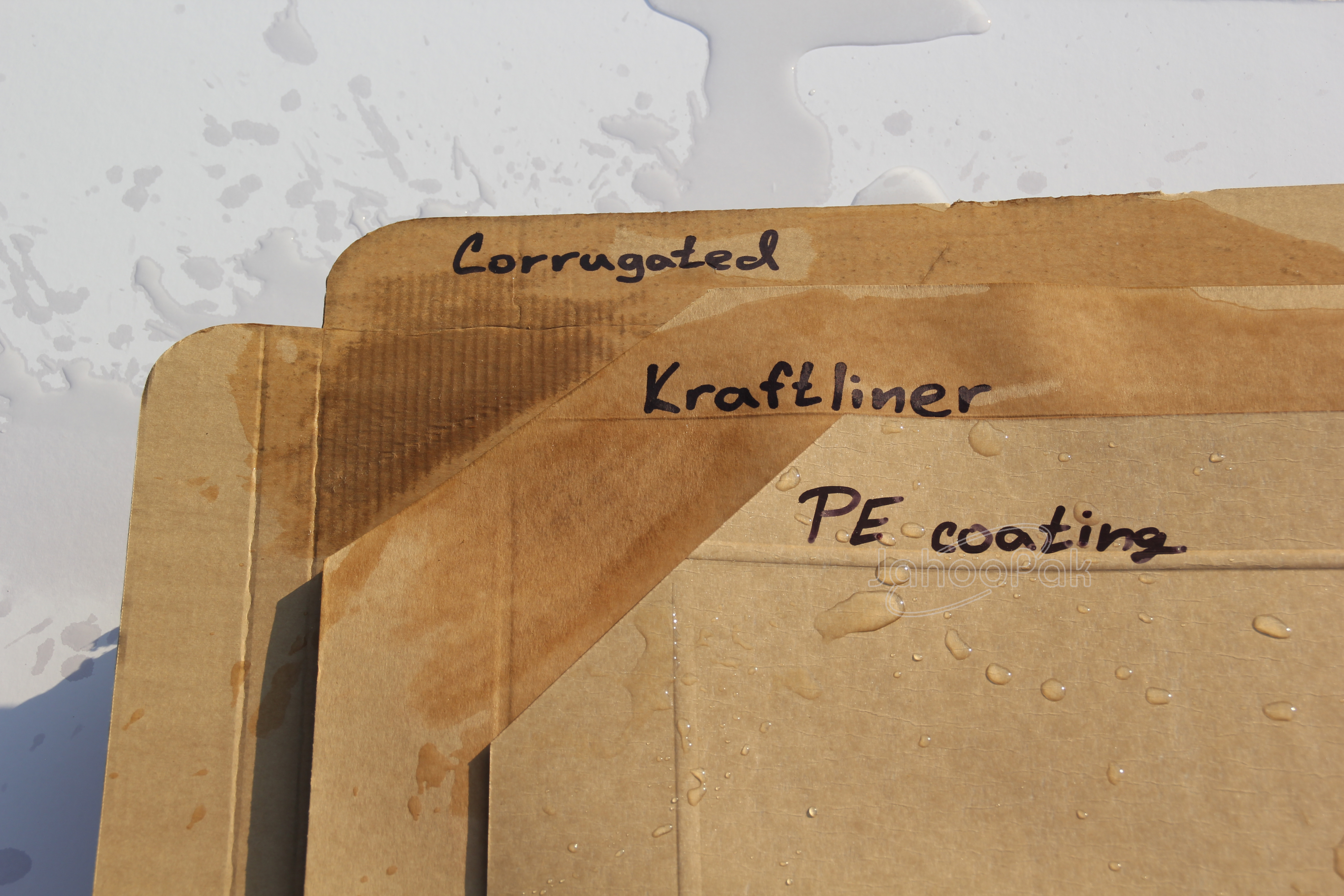

JahooPak paper slip sheets are made from 100% paper. We can also provide these sheets with a PE coating so that they are moisture-resistant. In addition we can provide the slip sheets with flaps (crease), making them easy to grab for a push pull system.

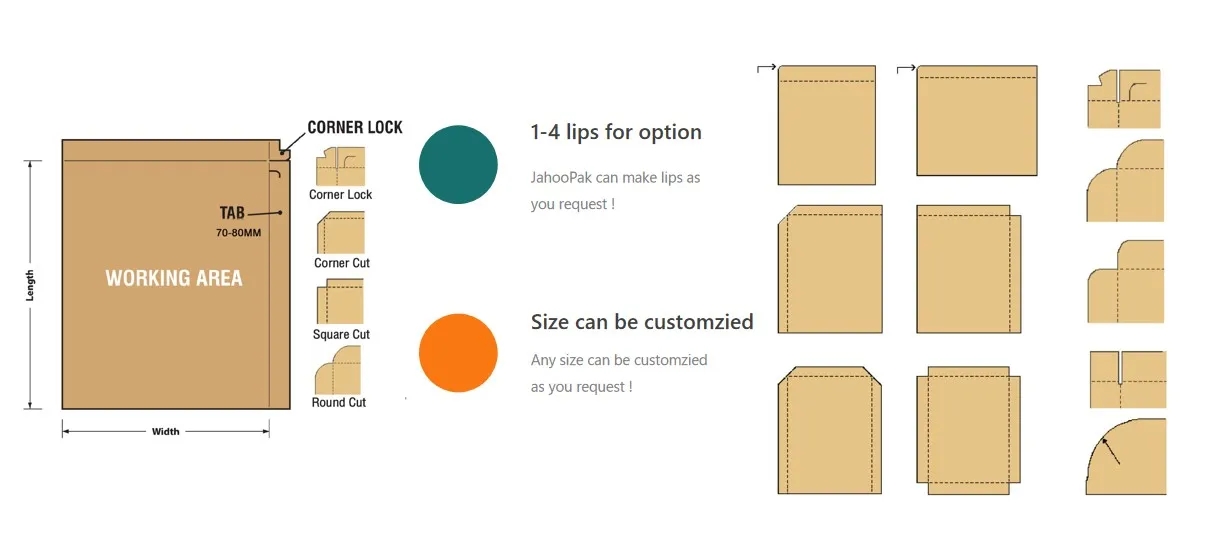

SLIP SHEETS comprise dividers made of a thin but very durable cardboard. They are manufactured to the same dimensions as a typical 800 mm x 1200 mm EUR pallet or a 1000 mm x 1200 mm pallet. On request other sizes can be produced. SLIP SHEETS can be provided with two or four “wings” (flaps) with a width of 60 mm used for picking up. The quantity and size of the flaps and their arrangement can be modified.

| 1 | Product name | slip sheet for transportation |

| 2 | Color | Kraft, Brown, Black |

| 3 | Usage | Warehouse & Transportation |

| 4 | Certification | SGS, ISO,etc. |

| 5 | Width of lip | Customizable |

| 6 | Thickness | 0.6~2mm or customized |

| 7 | Loading Weight | 300kg-1800kg (for 3003500kg, please visit our plastic slip sheet) |

| 8 | Special handling | Available (moistureproof) |

| 9 | OEM Option | Yes |

| 10 | Drawing picture | Customer offer / our design |

| 11 | Types | One-tab slip sheet; two-tab slip sheet-opposite; two-tab slip sheet-adjacent; three-tab slip sheet; four-tab slip sheet. |

| 12 | Benefits | 1.Reduce the cost of material,freight,labour,repair,storage and disposal |

| 2.Environmentally-friendly, wood-free, hygienic and 100% recyclable | ||

| 3.Compatible with standard forklifts outfitted with push-pull attachments, rollerforks and morden conveyor systems | ||

| 4.Ideal for both domestic and international shippers | ||

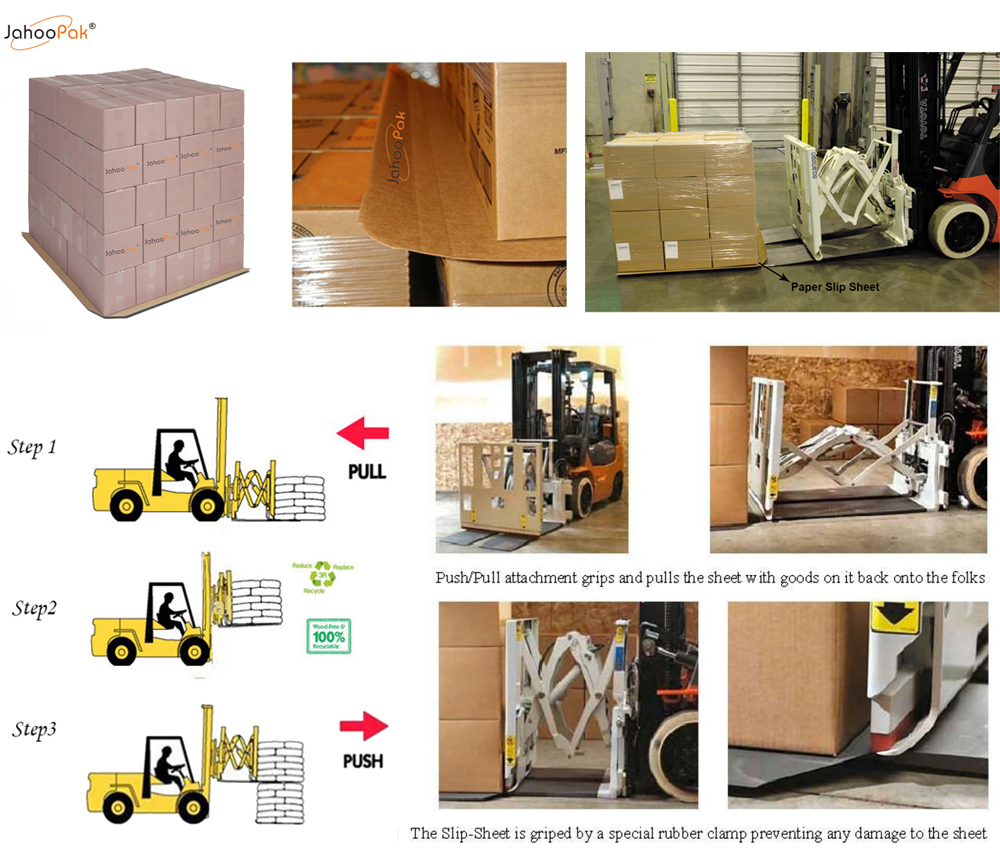

| 13 | BTW | For the use of slip sheets all you need is a push/pull-device, which you can get from your nearest fork-lift truck supplier. The device is suitable for any standard fork-lift truck and the investment repays itself faster than you would think. You will get more free container space and save in handling and purchasing costs. |

Product Details

Popular Style

How To Use?

Core Function & How It Works:

The primary function of a slip sheet is to consolidate a load. Goods are stacked and secured (usually with stretch wrap or straps) onto the sheet. A key feature is its lip (or tab), which is gripped by the clamp of a push-pull attachment on a forklift. The operator pulls the entire load onto the forks for transport and then pushes it off at the destination. This eliminates the need for a pallet to be physically lifted.

Production Line

Quality Control

Packing