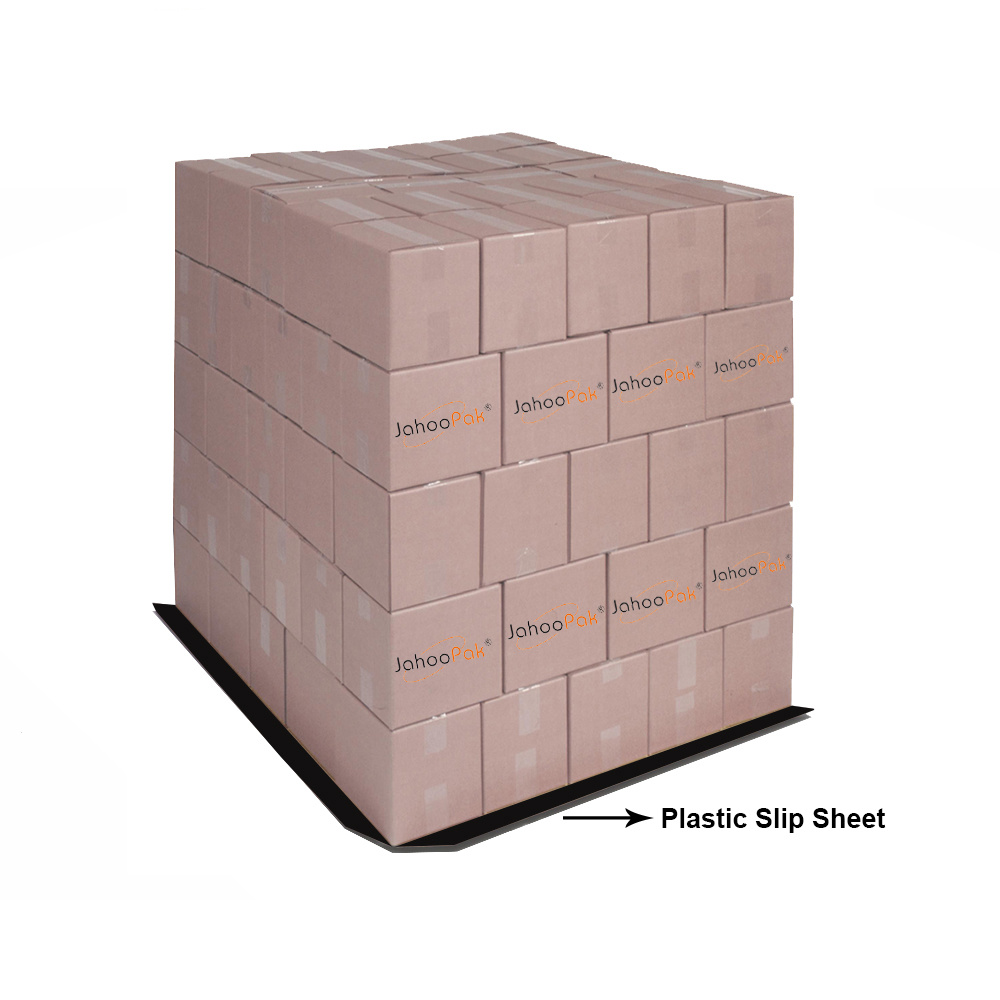

Provide Protection and Reduce Weight With Plastic Slip Sheets

To be successful in any business, you need to maximize productivity and reduce costs — and JahooPak slip sheet products help warehouses and product movers do just that. Slip Sheets are a great logistical option for those who are looking to save space in their warehouse, trailer or shipping container.

If you need to provide protection for your products while shipping them, but want to reduce the weight and bulk of pallets, consider using Cherry’s Industrial Equipment’s plastic slip sheets.

Manufactured with HDPE, these slip sheets are resistant to bacteria, moisture and tearing. Our slip sheets are easy to customized to fit load requirements, and can support up to 2,300 lbs. Choose from 22 sizes and styles, including four-tab, opposite-edge, single-edge and adjacent-edge construction. Our plastic slip sheets are also fully recyclable.

How Much Space Are You Wasting?

It can be shocking to see how much you’ll save if you switch to plastic slip sheets.

It isn’t uncommon for 10% or more of inadequately utilized space to be dedicated solely to pallets. Now imagine replacing that wasted space with extra product. In the case of a delivery truck, that can quickly add up to significant fuel and transport savings, too.

Our die cut, scored and coextruded plastic slip sheets have the durability to compete with the best pallets on the market. You can use our slip sheets to cube out your trailers and containers more effectively, maximize storage space in your warehouses and reduce loading and unloading time in your facility. Most importantly, you can use slip sheets to reduce your expenses.

What is a Slip Sheet?

A slip sheet is a thin, pallet-sized plastic sheet with at least one tab (or lip) that can often serve the same purposes as pallets in material handling applications. Slip sheets are most commonly made from HDPE and in some cases Polypropylene plastic and metals and metal alloys. When implementing slip sheets, the user typically secures the load with shrink wrap or stretch wrap to provide additional stability.

There are two basic slip sheet types: single-lip and multi-lip.

Single-lip slip sheets feature a lip that faces the unit load carrier, which maximizes space utilization and minimizes travel space clearance requirements. Multi-lip slip sheets are designed to allow loading from one side and unloading from the other, which is beneficial for freight handling applications on rail cars and ocean vessels.

What Are the Advantages of Using Plastic Slip Sheets?

More and more businesses are seeing the advantages of plastic slip sheets and using them to replace the number of pallets they use for stocking and transporting their materials and products. These advantages include:

- Space savings: Slip sheets are much thinner than pallets and take up less space when stacked with your containers or boxes. You can create as many layers as you like without eating into your valuable storage space. This is especially important during transport, where the use of pallets can mean significantly less space for product.

- Flexibility: The flexible nature of our plastic slip sheets means they account for slight differences in the height and flatness of your layers of products. Pallets require a flat surface for safe, stable packing. Uneven surfaces can allow a pallet to rock, and for items to fall off. Our plastic slip sheets will conform to the layer beneath them and allow for even stacking.

- Resistance: Our plastic slip sheets are suitable for damp and humid conditions, where wooden pallets might rot and allow for mold and bacteria growth. Slip sheets can easily be cleaned to remove dust, dirt and other debris. You can reuse our plastic slip sheets for years thanks to their strong durability.

- Ease of storage: Unlike pallets, which require sizeable storage space when not in use, plastic slip sheets can easily be piled or rolled up when you’re not using them. You can keep a stack of plastic slip sheets handy in multiple locations around your factory, warehouse or in your transport trucks so that you’re always ready to stack and store your products and materials.

- Strength: With the ability to withstand over 2,000 lbs., our plastic slip sheets can be used for a variety of storage and transportation requirements.

Slip Sheets Help You Save Space in Your Trucks and Warehouses

Your storage space is precious. Every square foot of floor space in your warehouse and shipping truck costs you money. When you stack products and materials, the pallets you use are taking up part of that space, and if you’re not economical, it can become wasted space. That can mean wasted money.

While some items absolutely need to be installed on a pallet for strength, portability and safety needs, slip sheets can provide a smarter, more efficient option for the more flexible items. Slip sheets are designed to create a separation between different layers of material or containers but take up less space than a pallet.

There are many situations in which a slip sheet is the best option for your storage and stacking needs, such as:

- When you have many layers of containers and boxes: If you have raw materials, components or finished products in boxes and containers, it can be useful to separate them into individual layers. A pallet for each layer could be overkill and take up too much space. However, using slip sheets allows you to separate your layers with a minimum of additional stack height, but efficient stacking strength.

- When you have small items to stack and move: Some small items aren’t suitable for stacking on pallets because they fall through the slats or don’t stay level. A slip sheet provides a flat surface that keeps all of your stacked objects together. You can also choose the texture and score that suits your needs in terms of adherence and flexibility.

- When you’re looking to reduce strain and effort when loading and unloading: Pallets are heavy, and removing then can take time, energy.Whereas removing a slip sheet once it is empty is fast and easy. You can pull it off by hand and roll it up or stack it with little effort.

Examples of industries that can make good use of plastic slips include frozen foods, consumer products, bakery and ingredients and food service, to name just a few.

Why Use Slip Sheets Instead of Pallets?

While pallets have long been the “traditional” method when stacking loads for shipping, more companies are discovering the advantages of converting to slip sheets. They allow for 12-15% more products in material handling containers, which represents significant space savings. They also reduce loading and unloading times by as much as 60%, which can dramatically lower your company’s material handling costs. It’s much easier to customize a slip sheet to the size of the load, which provides greater flexibility.