Dunnage container airbags are specifically designed to secure and stabilize cargo in containers, trucks, and ships. They provide a convenient and cost-effective way to ensure cargo stabilization during both lateral and longitudinal movement and are much more effective in stabilizing cargo than wood blocking and bracing. An airbag is applied by inserting it in the void of a load, usually between two loads. An airbag inflator is then used to inflate the airbag with compressed air. As the airbag fills up, its pressure pushes the load against the sidewalls of the trailer and locks the load in place. Most airbags take only seconds to fill.

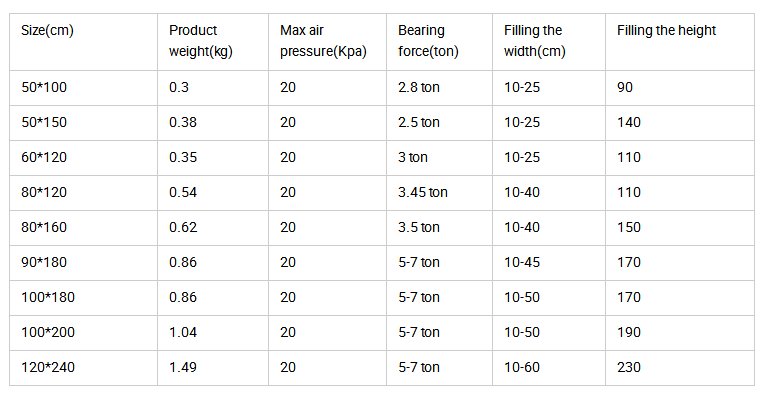

The type of Dunnage container bag required depends on a number of variables such as void size, cargo/load height, and shipping requirements. Dunnage container airbags are available in various sizes and materials (Kraft or Woven Polypropylene).

| )Brand | JahooPak |

| 2)Outside Materials | 75g Kraft Paper Laminated 75g PP Woven Fabric |

| 3)Inner Materials | 70um PA Film |

| 4)Body Color | Nature Brown Color |

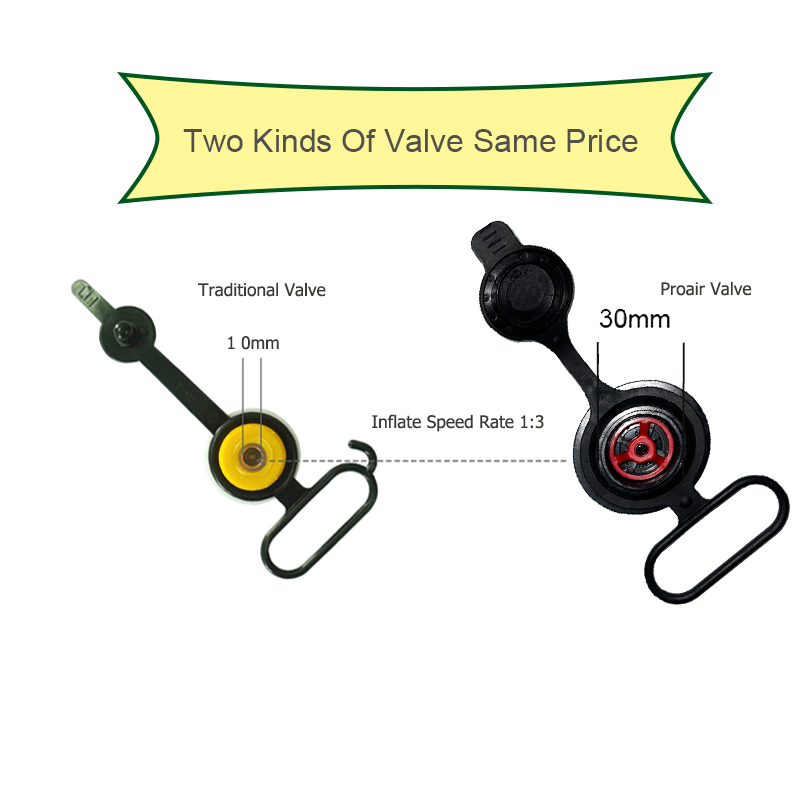

| 5)Valve | Traditional Standard Valve or New Inflate Valve |

| 6)Work Pressure | 3 PSI |

| 7)Size | 80*120cm or customized acceptable. |

| 8)Shipping Way | By sea/By air for mass production |

| DHL/Fedex/TNT/UPS/EMS for samples | |

| 9)Delivery Time | About 7-10 days for first 1*20GP shipment. |

| 10)Payment | T/T,L/C, Paypal/ Western Union and Etc. |

| JahooPak Advantage | 1.98% customers' satisfaction. |

| 2.Good quality meet with Europe, America, Mid East, Asia Market Standards and Demands. | |

| 3.Wonderful 14 years market experience help you easy to start business. | |

| 4. Flexible size with your Logo Printing on. Easy to make your own brand |

Product Details

Production Line

Quality Control

Application

Packing