Product profile

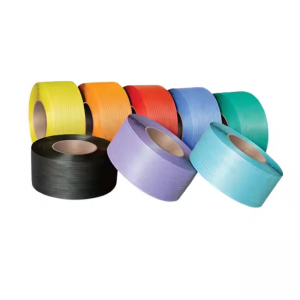

The PP strap band (Polypropylene strap band) is a type of plastic strapping commonly used for bundling, securing, and packaging goods. It is made from polypropylene, a durable and flexible thermoplastic polymer.

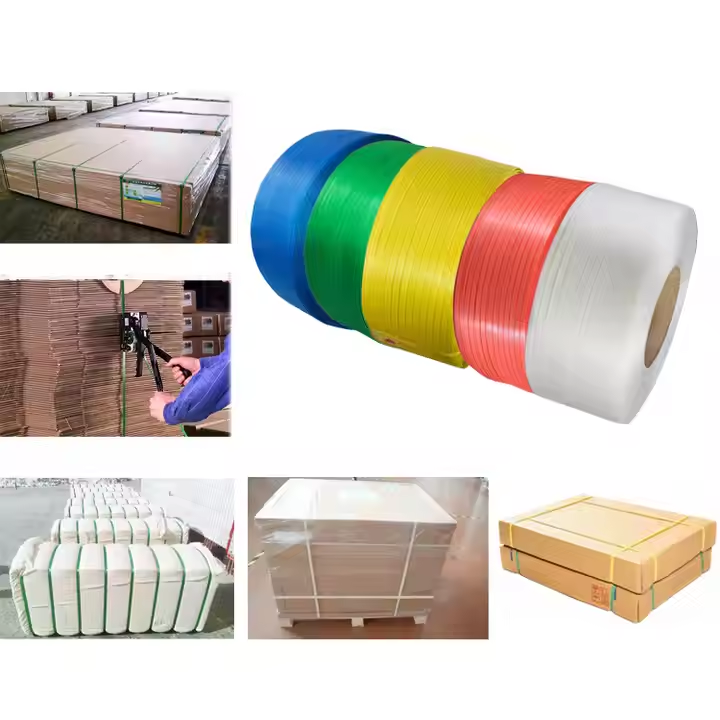

Product application

- Choose the right width & thickness – Depending on the load weight and application.

- Wrap around the items – Secure the strap around the package or pallet.

- Tensioning – Use a manual tensioning tool or machine to tighten the strap.

- Sealing – Secure the ends using a sealer (heat sealing or friction welding for a strong bond)

Why need use the pp strap band

- Cost-effective – Cheaper than steel or polyester strapping.

- Lightweight – Easy to handle and transport.

- Moisture & chemical resistant – Suitable for humid or corrosive environments.

- Good elongation – Absorbs shocks during transit.

- Recyclable – Environmentally friendly compared to metal straps.

The advantage of pp strap band

ABOUT US

Jiangxi JahooPak Co., Ltd. with 186 workers, 9800 square meter automated workshop, 19 years experience, AAR, SGS & ISO certificated, specializing in the production of Air Dunnage Bag, Slip Sheet, Paper Corner Protector, Container Seal, Cargo Bar, Stretch Film such those protective packaging products for transport solutions. In addition, JahooPak is 8 years’ vendor of Coca-Cola, Samsung and TCL. Quality is our highest priority and is carried out at every stage of production. Dedicated to strict quality control and thoughtful customer service, our experienced staff members are always available to discuss your requirements and ensure full customer satisfaction. In recent years, our company has introduced a series of advanced equipment. JahooPak continuously seeks to create the best and most cost-effective load protection solutions with a superior service for its customers and to have a safer World.