JahooPak plastic slip sheet is a thin, flat sheet made from durable plastic (often HDPE or UHMW) used in material handling and logistics as an alternative to traditional wooden or cardboard pallets. Here’s a breakdown of its features and uses:

Key Features:

- Material: High-density polyethylene (HDPE) or ultra-high-molecular-weight polyethylene (UHMW) for strength and smooth gliding.

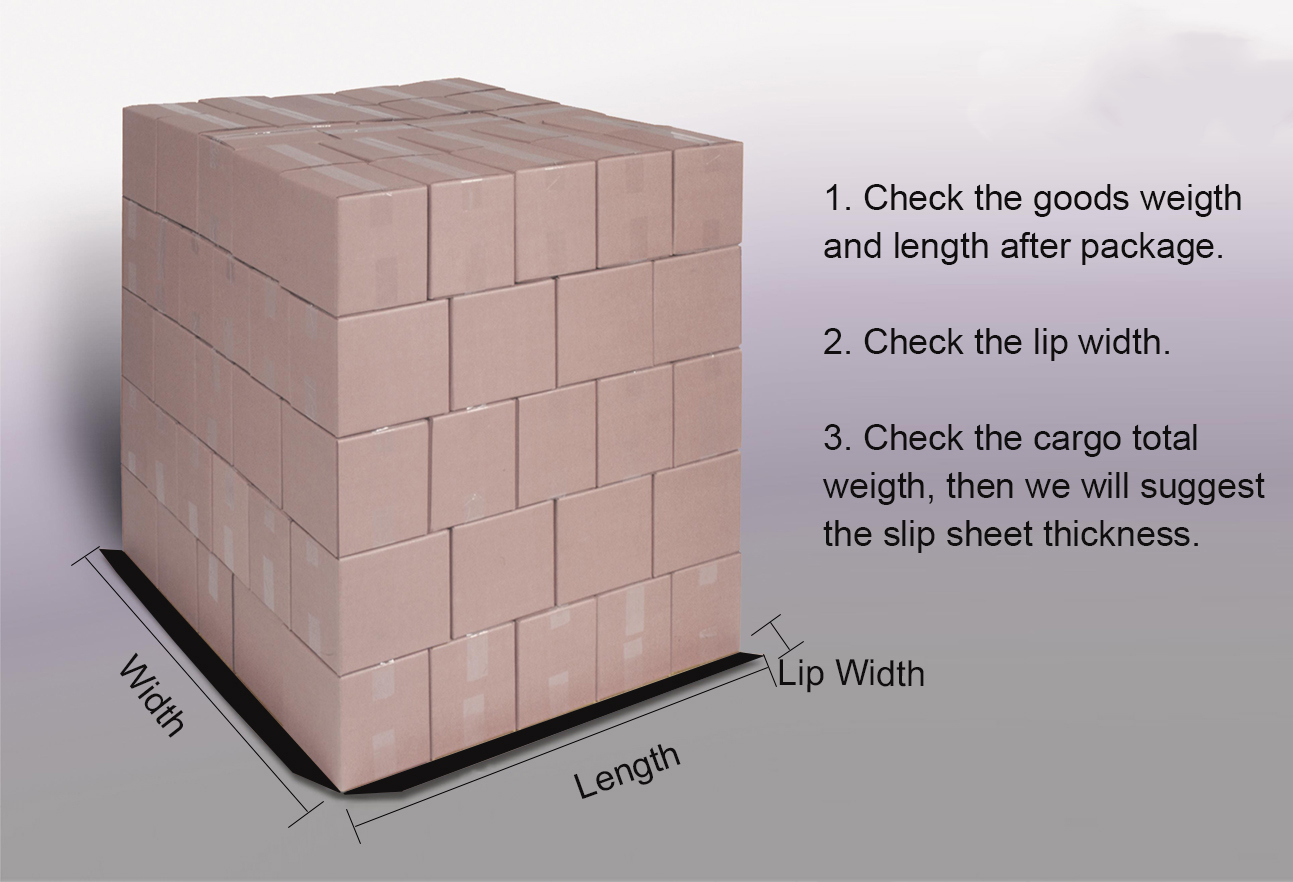

- Thickness: Typically 0.030” to 0.125” thick, lightweight yet sturdy.

- Size: Standard sizes mimic pallet dimensions (e.g., 48″ x 40″).

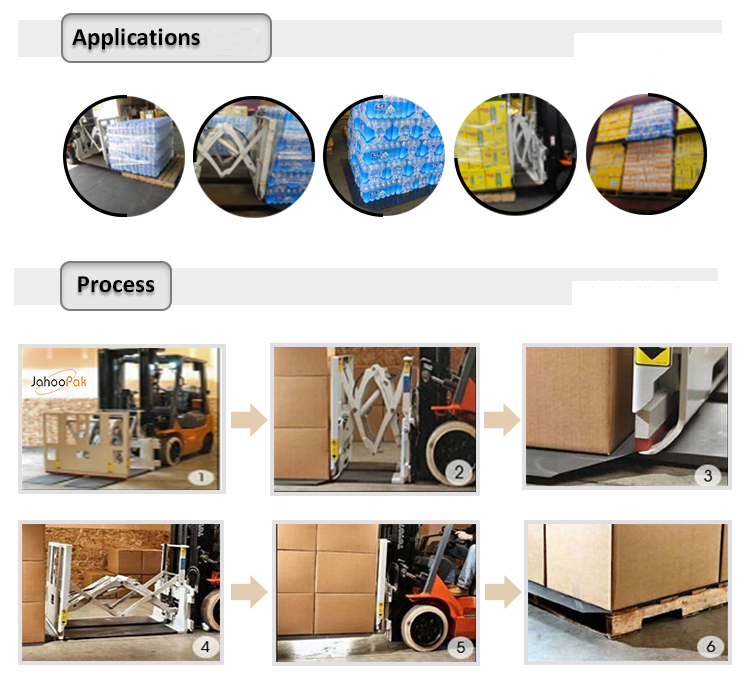

- Surface: Low-friction coating allows easy insertion/removal by forklifts with push-pull attachments.

- Reusable & Recyclable: More eco-friendly than single-use wood pallets.

Advantages:

- Space-Saving: Thinner than pallets, saving storage and shipping space.

- Cost-Efficient: Reduces pallet weight, lowering freight costs.

- Hygienic: Non-porous, easy to clean (ideal for food/pharma industries).

- Durable: Resists moisture, chemicals, and pests (unlike wood).

- Ergonomic: Reduces manual handling risks compared to heavier pallets.

Common Uses:

- Warehousing: Unit load stabilization for stacked goods.

- Shipping: Replaces pallets in containers (more cargo fits per trip).

- Retail/DC: Used in automated systems for smooth transport.

- Export Packaging: Avoids ISPM-15 wood treatment regulations.

Disadvantages:

- Requires special forklift attachments (push-pull or slider mechanisms).

- Less rigid than wood pallets; not ideal for uneven loads.

- Higher upfront cost than disposable options (but long-term savings).

Alternatives Comparison:

- Wood Pallets: Cheaper but bulkier, prone to damage.

- Cardboard Slipsheets: Ultra-lightweight but single-use.

- Plastic Pallets: More durable but heavier and costlier.

Best For:

Businesses prioritizing shipping efficiency, cleanliness, and cost savings over long hauls or automated systems.