Product profile

A PP (Polypropylene) Woven Air Dunnage Bag is an inflatable cargo securement device made from high-strength woven polypropylene fabric, designed to fill gaps and prevent load shifting in shipping containers, trucks, or rail cars. These bags are lightweight, reusable, and provide excellent burst resistance and impact absorption during transit.

Product application

1. Select the Right Size

- Measure the gap between cargo pallets or boxes.

- Choose a bag slightly larger than the gap (e.g., for a 30cm gap, use a 35-40cm bag).

2. Position the Bag Properly

- Place the deflated bag vertically or horizontally in the empty space.

- Ensure it sits evenly between cargo, not folded or pinched.

3. Inflate the Bag

- Use an air pump (hand pump, electric pump, or compressor).

- Inflate to recommended pressure (usually 0.15-0.35 bar / 2-5 PSI).

- Do not overinflate (risk of bursting) or underinflate (ineffective support).

4. Secure & Inspect

- Check that the bag is firm but slightly compressible.

- Ensure cargo is tightly packed with no movement.

5. Deflate & Reuse After Shipping

- After unloading, puncture the valve to release air.

- Fold and store for future use.

Why need use the air dunnage bag for container ?

1. Prevent Cargo Shifting During Transit

- Containers experience vibrations, sudden stops, and tilting during transport (by ship, truck, or rail).

- Air dunnage bags fill empty spaces between cargo, securing items in place and preventing movement that could cause damage.

2. Protect Goods from Impact & Crushing

- They act as a cushion, absorbing shocks and reducing the risk of breakage, scratches, or deformation.

- Especially useful for fragile, high-value, or unevenly shaped loads.

3. Cost-Effective & Efficient Load Stabilization

- Cheaper and faster than traditional methods like wooden bracing or foam blocks.

- Lightweight, taking up minimal space when deflated.

4. Versatile & Adaptable

- Can fit irregular gaps in containers, pallets, or trucks.

- Adjustable inflation allows customization based on load requirements.

5. Reduce Labor & Handling Time

- Quick to install and remove compared to manual blocking and bracing.

- Reusable (if undamaged), saving long-term costs.

6. Improve Safety & Compliance

- Prevents accidents caused by shifting cargo (e.g., container door bursts).

- Meets international shipping standards (like IMO/CTU guidelines).

The advantage of air dunnage bag

1. Superior Cargo Protection

- Prevents Shifting: Fills voids between pallets or goods, keeping them from moving during transit.

- Absorbs Shock & Vibration: Acts as a cushion against impacts, reducing damage risks.

- Distributes Pressure Evenly: Prevents crushing or deformation of sensitive goods.

2. Cost-Effective Solution

- Cheaper than Wood/Metal Bracing: No need for expensive timber, steel frames, or foam blocks.

- Reusable (If Undamaged): Can be deflated, stored, and reused for multiple shipments.

- Reduces Insurance Claims: Fewer damaged goods mean lower losses and claims.

3. Fast & Easy to Use

- Quick Installation: Simply place the bag in gaps and inflate (manually or with an air pump).

- No Special Skills Needed: Faster than manual blocking and bracing.

- Lightweight & Compact: Takes minimal storage space when deflated.

4. Versatile for Different Cargo Types

- Fits Irregular Gaps: Adapts to uneven spaces between pallets, boxes, or machinery.

- Works in Various Transport Modes: Containers, trucks, rail cars, and sea freight.

- Suitable for Fragile & Heavy Loads: Protects electronics, glass, automotive parts, etc.

5. Enhances Safety & Compliance

- Prevents Accidents: Stops cargo from shifting and bursting container doors.

- Meets IMO/CTU Guidelines: Complies with international shipping safety standards.

6. Eco-Friendly Option

- Reduces Waste: Unlike single-use wood bracing, air bags can be reused.

- Some Are Recyclable: Certain bags are made from recyclable materials.

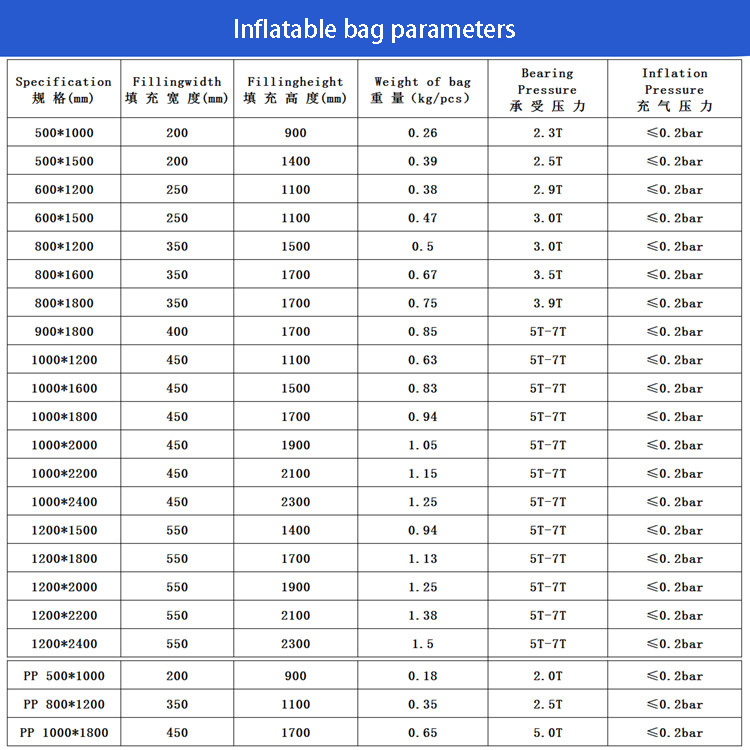

Common specifications

Company profile