Product profile

Stretch film (also called stretch wrap) is a highly stretchable plastic film (usually made from LLDPE – Linear Low-Density Polyethylene) that is used to wrap and secure items on pallets or bundles. It clings to itself and the load, providing stability and protection during storage and transportation.

Product application

- Manual Wrapping (Hand Stretch Film):

- Hold the film roll and start at the base of the pallet.

- Wrap in a spiral motion, overlapping layers by about 50% for stability.

- Apply tension to ensure a tight wrap.

- Finish at the top, tucking the end under a layer to secure it.

- Machine Wrapping (For Large Loads):

- Use a stretch wrapper machine (semi-automatic or automatic).

- Place the pallet on the turntable, and the machine rotates while dispensing film.

- Ensures consistent tension and reduces labor costs.

- Types of Wrapping Methods:

- Spiral Wrapping – Standard method for uniform loads.

- Horizontal (Band) Wrapping – Reinforces the top and bottom.

- Cage Wrapping – For irregularly shaped items.

Why need use the stretch film for goods

- Load Stability – Prevents items from shifting or falling during transit.

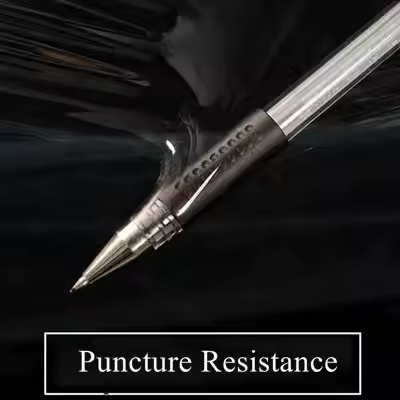

- Protection – Shields goods from dust, moisture, and minor impacts.

- Tamper Evidence – Unauthorized access is visible if the film is torn.

- Cost-Effective – Cheaper than strapping or shrink wrapping.

- Space Efficiency – Keeps palletized goods tightly packed, optimizing storage.

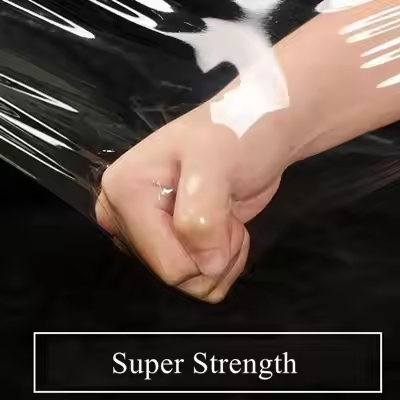

The advantage of stretch film

✅ High Stretchability – Can stretch up to 300%, reducing material usage.

✅ Strong Cling – Sticks to itself without adhesives.

✅ Lightweight – Adds minimal weight to shipments.

✅ Versatile – Works for various load types (boxes, furniture, machinery).

✅ UV-Resistant Options – Some films protect against sunlight degradation.

✅ Recyclable – Many stretch films are recyclable (LLDPE).

Different type of stretch film

- Hand Stretch Film – For light to medium loads.

- Machine Stretch Film – Thicker, for automated wrapping.

- Pre-Stretched Film – Requires less force to apply.

- Vented Film – Allows airflow (for fresh produce).

- Colored/Printed Film – For branding or load identification.

Company profile