Dunnage air bags are highly effective but must be used correctly to ensure safety.

- NEVER Over-Inflate: A bag should be inflated until it is firm and makes full contact with the load. Over-inflation can lead to bursting, which is dangerous and renders the bag useless. A common rule is to inflate until the bag’s width fills about 90% of the void space.

- ALWAYS Use Header Boards: Never place an air bag directly against cargo. The uneven surface can cause punctures. Header boards distribute the pressure evenly and protect both the bag and the cargo.

- Inspect the Environment: Check the interior of the trailer for sharp protrusions, nails, or broken panels that could puncture the bag.

- Proper Placement: Ensure the bag is placed on a flat, stable surface and is centered within the void space.

- Training is Essential: Drivers and warehouse staff must be trained on proper inflation and placement procedures to prevent accidents and ensure optimal performance.

Product Details

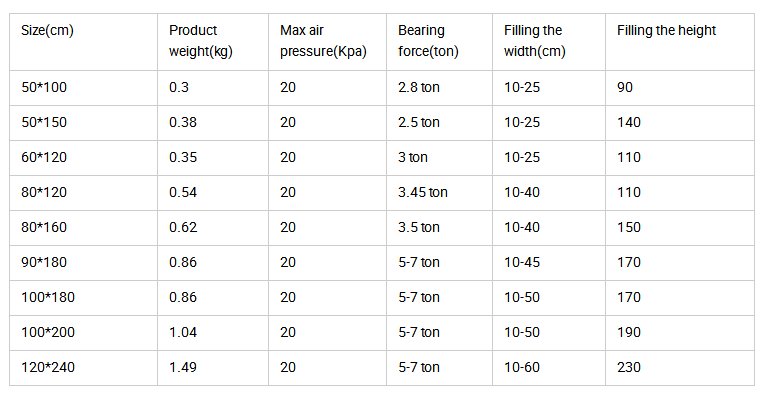

| )Brand | JahooPak |

| 2)Outside Materials | 75g Kraft Paper Laminated 75g PP Woven Fabric |

| 3)Inner Materials | 70um PA Film |

| 4)Body Color | Nature Brown Color |

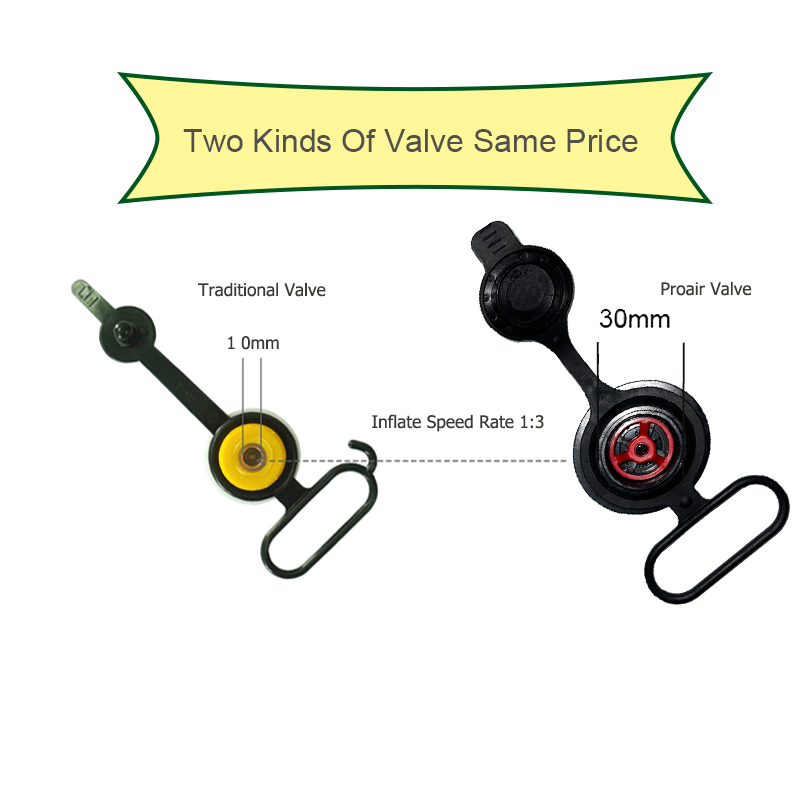

| 5)Valve | Traditional Standard Valve or New Inflate Valve |

| 6)Work Pressure | 3 PSI |

| 7)Size | 80*120cm or customized acceptable. |

| 8)Shipping Way | By sea/By air for mass production |

| DHL/Fedex/TNT/UPS/EMS for samples | |

| 9)Delivery Time | About 7-10 days for first 1*20GP shipment. |

| 10)Payment | T/T,L/C, Paypal/ Western Union and Etc. |

| JahooPak Advantage | 1.98% customers’ satisfaction. |

| 2.Good quality meet with Europe, America, Mid East, Asia Market Standards and Demands. | |

| 3.Wonderful 14 years market experience help you easy to start business. | |

| 4. Flexible size with your Logo Printing on. Easy to make your own brand |

Production Line

Quality Control

Application

Packing