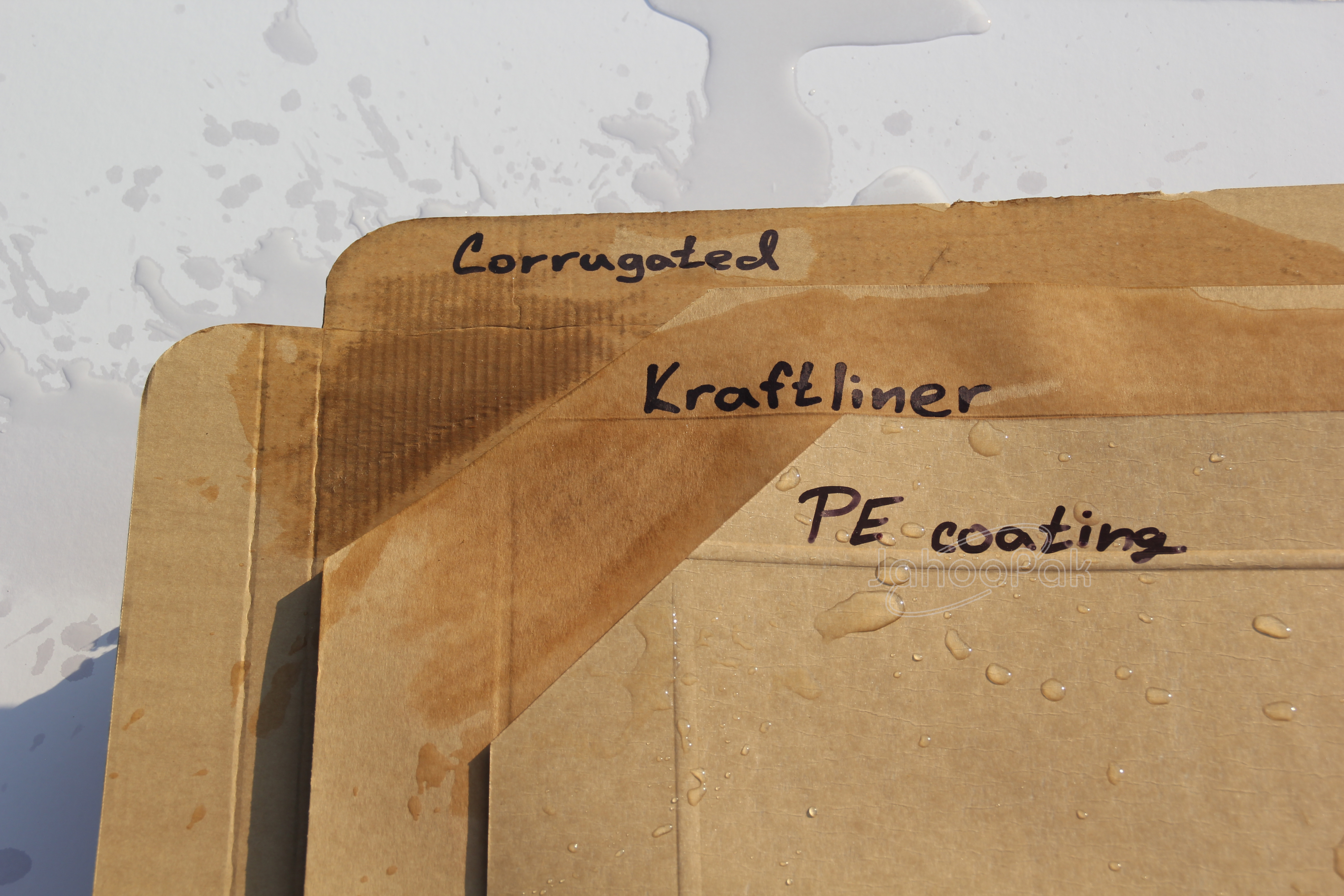

SLIP SHEETS can be covered with an anti-slip coating or plastic coating on one side or be entirely made of plastic to be water resistant.

The strength of individual dividers depends on their thickness. They can carry weights of 600 kg to 1800 kg.

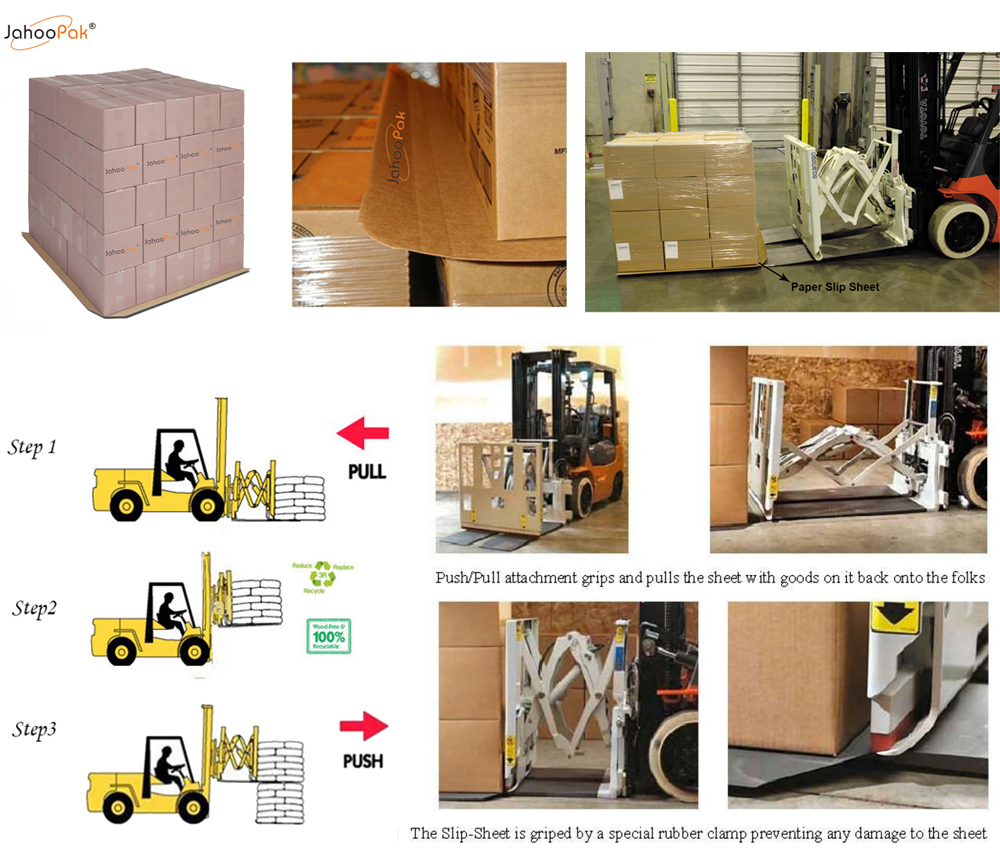

SLIP SHEETS are handled by special equipment called PUSH PULL.

They are covers intended for fast and simple mounting on popular forklifts, both battery-powered and diesel.

PUSH PULL and SLIP SHEETS allow the efficient movement of goods within the warehouse as well as quick loading and unloading of different means of transport, such as trucks, containers, etc. They constitute a modern system replacing the existing work methods.

| 1 | Product name | slip sheet for transportation |

| 2 | Color | Kraft, Brown, Black |

| 3 | Usage | Warehouse & Transportation |

| 4 | Certification | SGS, ISO,etc. |

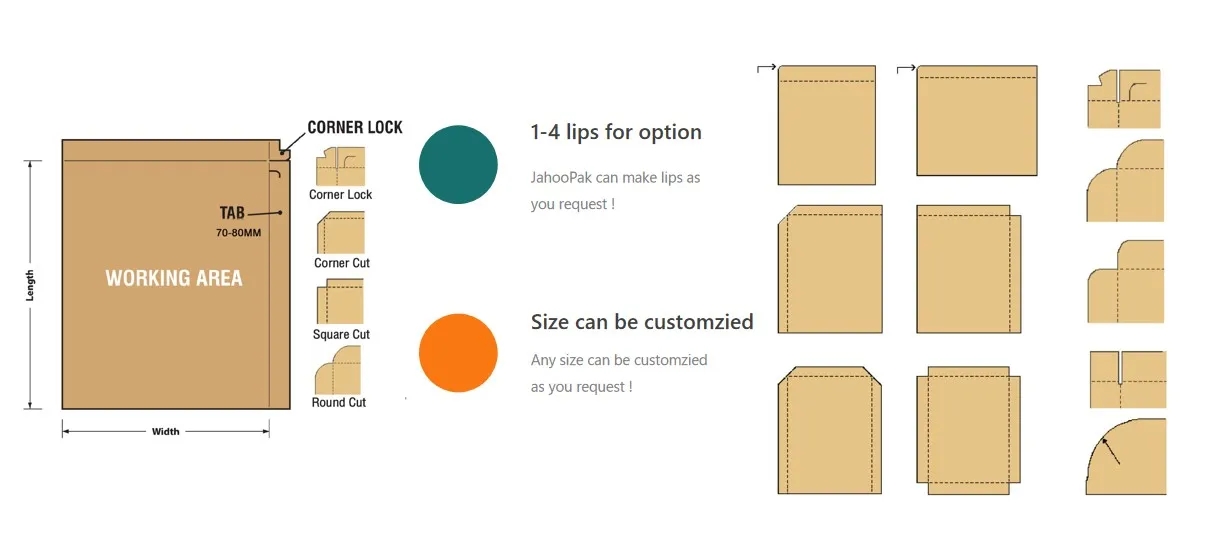

| 5 | Width of lip | Customizable |

| 6 | Thickness | 0.6~2mm or customized |

| 7 | Loading Weight | 300kg-1800kg (for 3003500kg, please visit our plastic slip sheet) |

| 8 | Special handling | Available (moistureproof) |

| 9 | OEM Option | Yes |

| 10 | Drawing picture | Customer offer / our design |

| 11 | Types | One-tab slip sheet; two-tab slip sheet-opposite; two-tab slip sheet-adjacent; three-tab slip sheet; four-tab slip sheet. |

| 12 | Benefits | 1.Reduce the cost of material,freight,labour,repair,storage and disposal |

| 2.Environmentally-friendly, wood-free, hygienic and 100% recyclable | ||

| 3.Compatible with standard forklifts outfitted with push-pull attachments, rollerforks and morden conveyor systems | ||

| 4.Ideal for both domestic and international shippers | ||

| 13 | BTW | For the use of slip sheets all you need is a push/pull-device, which you can get from your nearest fork-lift truck supplier. The device is suitable for any standard fork-lift truck and the investment repays itself faster than you would think. You will get more free container space and save in handling and purchasing costs. |

Product Details

Popular Style

How To Use?

Core Function & How It Works:

The primary function of a slip sheet is to consolidate a load. Goods are stacked and secured (usually with stretch wrap or straps) onto the sheet. A key feature is its lip (or tab), which is gripped by the clamp of a push-pull attachment on a forklift. The operator pulls the entire load onto the forks for transport and then pushes it off at the destination. This eliminates the need for a pallet to be physically lifted.

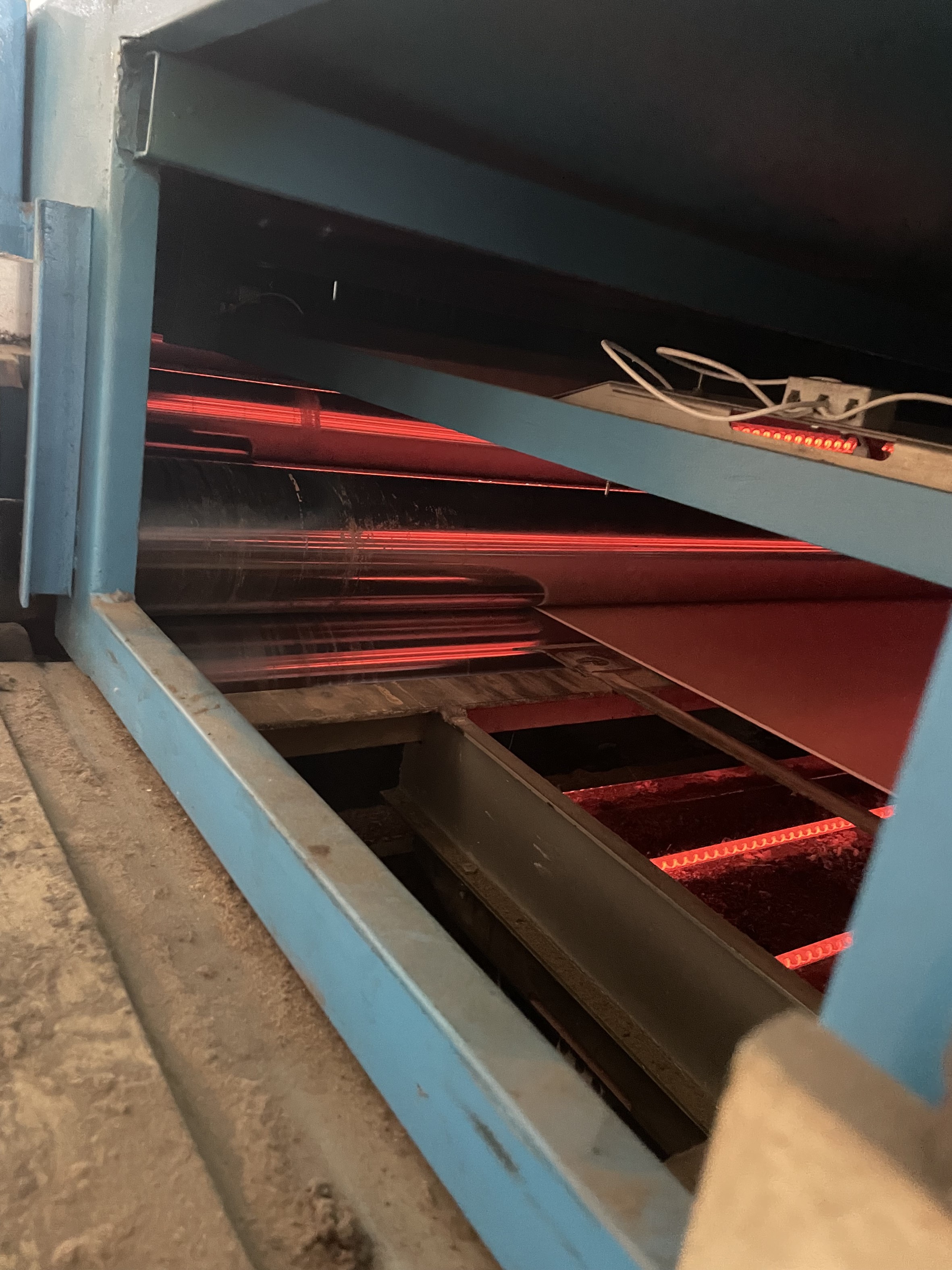

Production Line

Quality Control

Packing