Product profile

A kraft paper slip sheet is a thin, sturdy sheet made from heavy-duty kraft paper (often 2-5mm thick) used as a pallet-free base for transporting and storing goods. It serves as a lightweight, cost-effective alternative to wooden or plastic pallets, designed for use with forklift push-pull attachments.

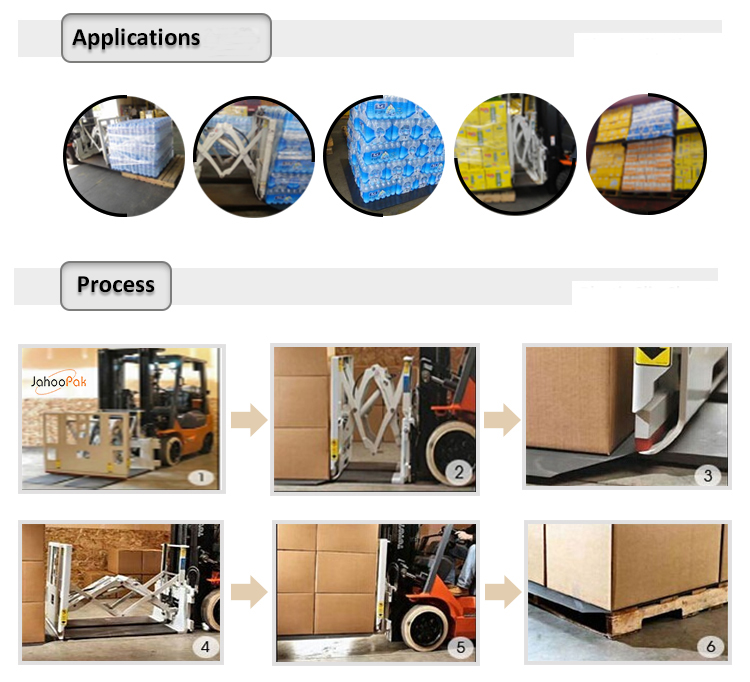

Product application

1. Preparing the Load

- Place the slip sheet on a flat, stable surface.

- Stack products evenly on top (just like palletizing).

- Secure the load with stretch wrap, straps, or adhesive to prevent shifting.

2. Handling with a Forklift (Push-Pull Attachment Required)

- Step 1: The forklift operator positions the push-pull clamp over the extended lip (called the ”tab”).

- Step 2: The clamp grips the tab and pulls the slip sheet (with the load) onto the forklift’s platform.

- Step 3: To unload, the forklift pushes the slip sheet off onto the ground or rack.

3. Alternative Handling Methods

- Manual Handling (for lighter loads): Workers can slide the slip sheet using the tab.

- Pallet-Compatible Use: Can be placed on top of a pallet for extra stability.

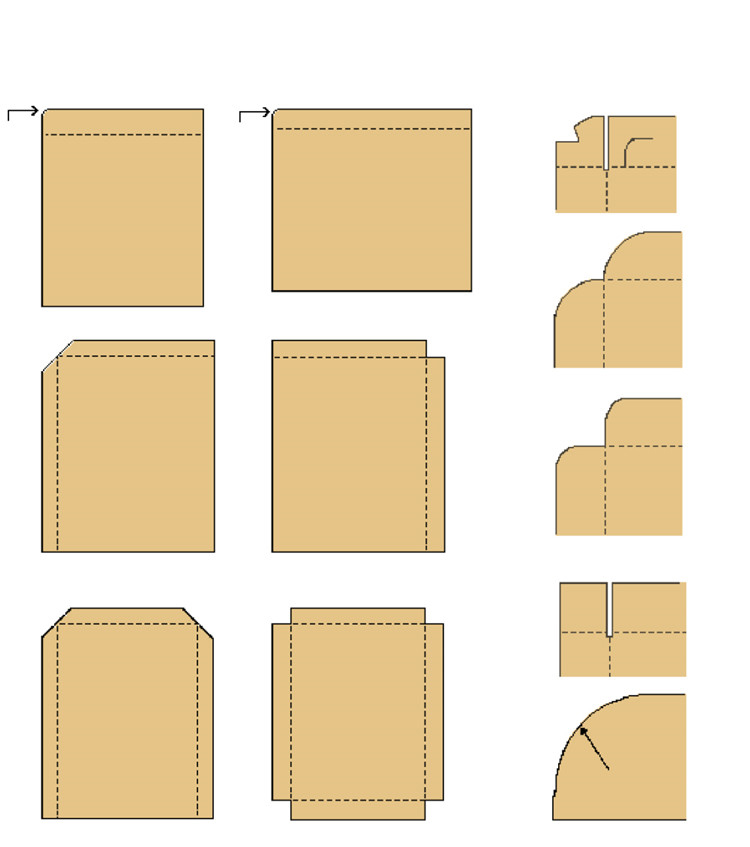

Different type of corner and lip

Why the slip sheet is more popular than traditional pallet

1. Cost Efficiency

- Lower Material Cost: Slip sheets are made from thin, durable materials (like corrugated fiberboard or plastic), which are cheaper than wooden or plastic pallets.

- Reduced Shipping Costs: Since they are lightweight and flat, slip sheets save on freight weight and maximize container space (no pallet height or weight).

- No Pallet Return or Disposal Fees: Unlike pallets, slip sheets are often disposable or reusable without the need for reverse logistics.

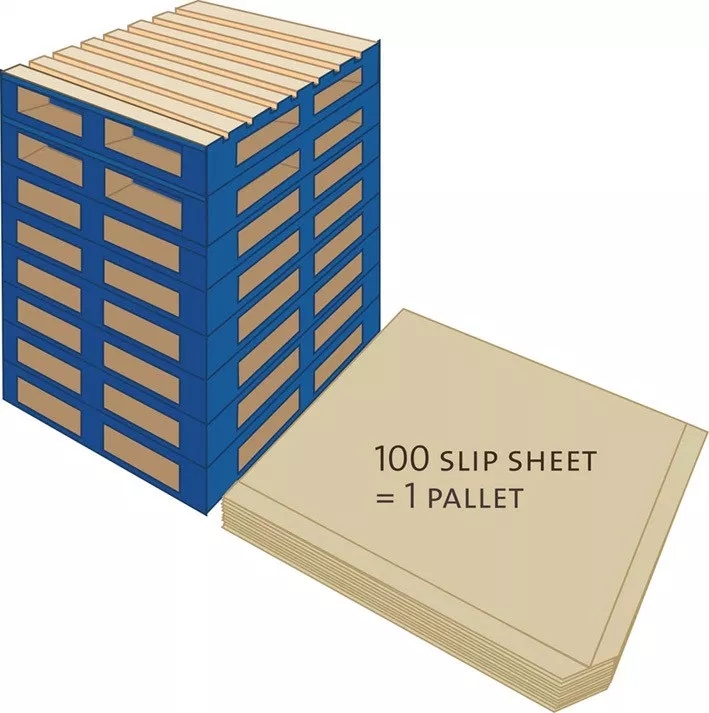

2. Space Savings

- Compact Storage: Slip sheets take up minimal space compared to bulky pallets, allowing more efficient warehousing and shipping.

- Higher Load Capacity per Container: Without pallet height restrictions, more goods can fit in a truck or shipping container.

3. Sustainability & Eco-Friendliness

- Less Material Waste: Slip sheets use fewer raw materials than pallets, reducing environmental impact.

- Recyclable & Lightweight: Many are made from recyclable materials, lowering carbon footprint in transport.

4. Improved Handling Efficiency

- Faster Loading/Unloading: With push-pull attachments or forklift clamps, slip sheets allow quick handling without manual pallet handling.

- Automation-Friendly: Ideal for automated warehouses and robotic systems, as they require less space and can be easily integrated into conveyor systems.

5. Better Hygiene & Safety

- No Nails or Splinters: Unlike wooden pallets, slip sheets eliminate the risk of product damage or worker injuries from broken pallets.

- Sanitary Benefits: Plastic or coated slip sheets are easier to clean, making them ideal for food, pharmaceuticals, and cleanroom environments.

6. Customization & Flexibility

- Tailored Sizes & Materials: Slip sheets can be customized for different load types (e.g., anti-slip coatings for fragile goods).

- Compatible with Unit Loads: They work well with stretch wrap or strapping, securing loads just as effectively as pallets.

The advantage of slip sheet

1. Cost Savings

- Lower material cost – Made from affordable corrugated fiberboard, plastic, or laminated sheets.

- Reduced shipping expenses – Lighter weight = lower freight costs; no wasted space from pallet height.

- No pallet management – Eliminates pallet return, repair, or disposal fees.

2. Space & Storage Efficiency

- Ultra-thin design – Saves up to 90% storage space vs. bulky pallets.

- Maximizes container capacity – Fits more goods per truck/shipping container (no pallet footprint).

3. Sustainability Benefits

- Eco-friendly materials – Often recyclable or biodegradable (e.g., paperboard).

- Lower carbon footprint – Reduced transport weight and fewer raw materials used.

4. Logistics Optimization

- Faster handling – Push-pull forklift attachments enable quick loading/unloading.

- Automation-ready – Ideal for robotic warehouses and conveyor systems.

- Better load stability – Compatible with stretch wrap, straps, or interlocking designs.

5. Hygiene & Safety

- No splinters/nails – Safer for workers and products vs. wooden pallets.

- Cleanroom-friendly – Plastic or coated slip sheets meet food/pharma hygiene standards.

6. Customization & Versatility

- Tailored sizes/thicknesses – Adaptable to different loads (e.g., anti-slip coatings for glass).

- Multi-industry use – Ideal for retail, food/beverage, manufacturing, and export-heavy operations.

Here are the key features of paper slip sheets, which make them a popular choice in logistics and shipping:

1. Lightweight & Space-Saving

- Much lighter than wooden or plastic pallets, reducing shipping weight and costs.

- Saves storage space since they can be stacked flat when not in use.

2. Eco-Friendly & Sustainable

- Made from recyclable kraft paper or corrugated fiberboard.

- Biodegradable and compliant with green packaging regulations.

3. Cost-Effective Alternative to Pallets

- Lower material and handling costs compared to traditional pallets.

- Reduces freight expenses due to lighter weight.

4. High Load-Bearing Capacity

- Reinforced designs can support heavy loads (typically 1-2 tons).

- Some models have anti-slip coatings for better stability.

5. Compatible with Forklifts & Push-Pull Systems

- Works with specialized forklift attachments (push-pull or clamp mechanisms).

- Improves loading/unloading efficiency in automated warehouses.

6. Customizable Sizes & Thicknesses

- Can be tailored to fit different cargo dimensions (standard or custom sizes).

- Available in single or multi-layer constructions for varying strength needs.

7. Water-Resistant & Tear-Resistant Options

- Some are coated or laminated for moisture protection.

- High-quality kraft paper resists tearing during handling.

8. Improves Shipping Efficiency

- Enables palletless shipping, maximizing container space.

- Reduces labor costs with faster loading/unloading compared to pallets.

9. Safe for Food & Pharmaceutical Use

- Non-toxic and meets food-grade packaging standards (FDA, EU compliance).

10. Reduces Carbon Footprint

- Lower transportation emissions due to reduced weight.

- Supports sustainable supply chain initiatives.

Common Applications:

✔ Export packaging (replacing wooden pallets in international shipments)

✔ Automated warehouses (compatible with conveyor systems)

✔ Retail & grocery distribution (food-safe, lightweight)

✔ E-commerce fulfillment (space-saving for bulk orders)